We specialize in welding services using the latest technology and a team of highly trained welders. Our dedication to quality ensures that every weld meets the highest standards of precision. Here’s a detailed overview of our welding capabilities:

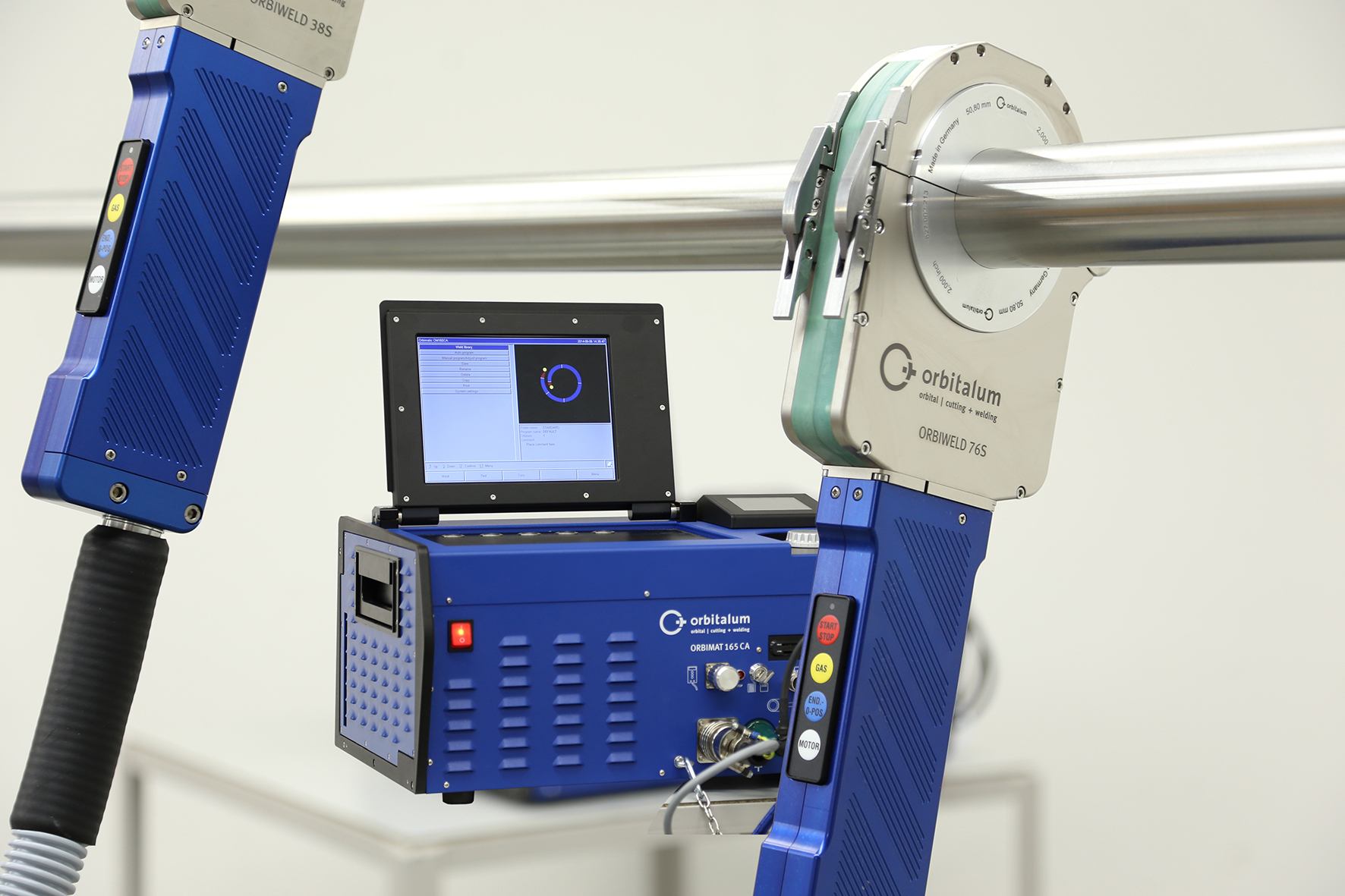

Orbital Welding Machine

TIG Welding Machine

Arc Welding Machine

Laser Welding Machine

Our Commitment to Quality

-

Advanced Technology : We continuously invest in the latest welding technologies to ensure we deliver precise and efficient welding solutions. Our equipment is regularly updated to incorporate the newest advancements in welding technology, allowing us to tackle even the most challenging projects.

-

Qualified Welders : Our team of welders is highly trained and certified, with extensive experience in various welding techniques. They undergo continuous training to stay updated with the latest welding standards and practices, ensuring top-notch results for every job.

-

Third-Party Inspection : To maintain the highest standards of quality, we conduct rigorous third-party inspections on all our welding projects. This ensures compliance with industry standards and provides an extra layer of assurance for our clients.

-

Customer-Specific Materials : We understand that each project has unique requirements. Therefore, we source and use materials based on the specific needs of our customers. This customization ensures that the final product meets or exceeds the required specifications and performance criteria.