At Fiumetech, our focus is on delivering top-tier services to the oil & gas, marine, steel, and other industries. Our advanced facilities and skilled workforce ensure that we meet and exceed our clients' expectations. As we continue to invest in and expand our capabilities, our facilities are becoming even more advanced to keep pace with industry demands. Take a look at the advanced facilities we have to offer:

Welding

We offer an extensive range of welding services, utilizing the latest technology and techniques. Our welding facilities are manned by qualified welders who ensure each job is completed to the highest standard. We operate six machines, including those capable of welding 4-inch and 5-inch pipes.

Drill Machine

Our high-precision drill machines are equipped with advanced control systems, allowing for accurate drilling operations across various materials. These machines are capable of handling complex drilling patterns with minimal error, ensuring optimal results for industrial applications.

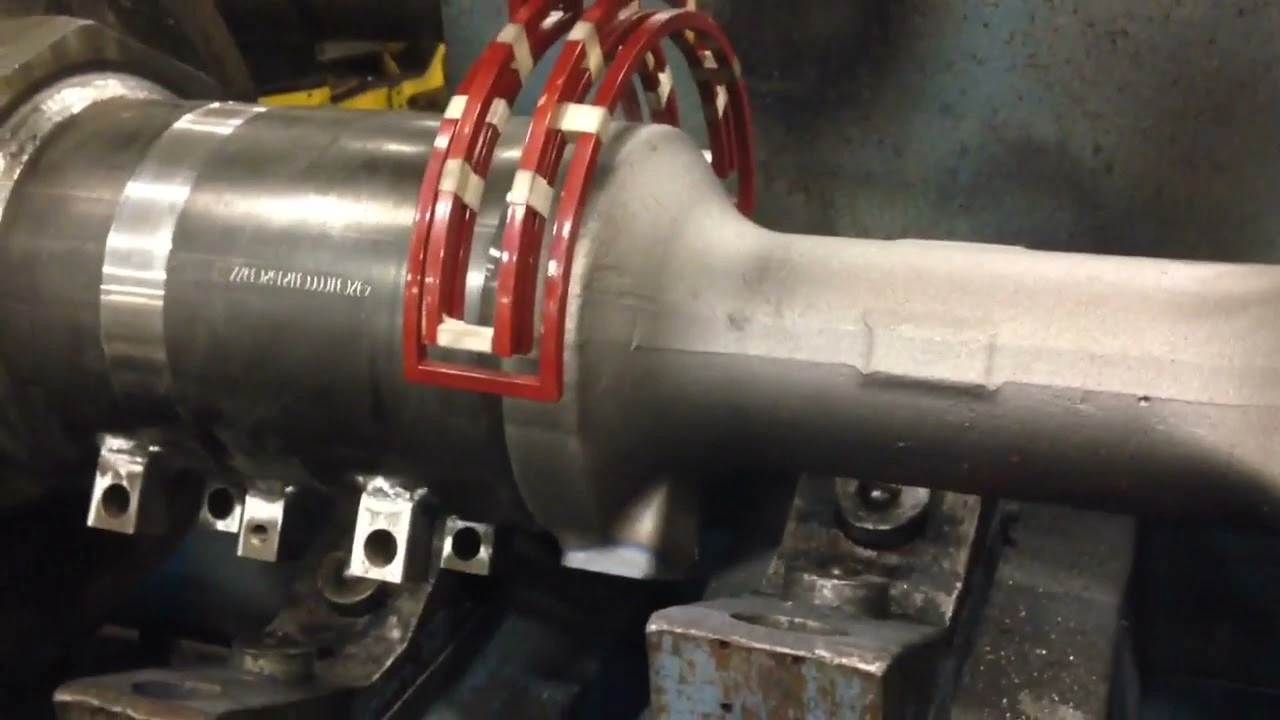

Lathe Machine

Our lathe machines are designed to handle all your machining needs with precision and care. We offer both CNC and manual lathes, each suited for a variety of tasks, from large-diameter turning to intricate thread cutting and custom machining. Our advanced equipment, combined with the expertise of our skilled technicians, ensures that every component we produce meets the highest standards of quality and accuracy. Whether you're in the oil & gas, marine, steel, or any industry, we're dedicated to delivering reliable, durable parts that truly make a difference in your operations.

In-Situ Machine

Our in situ machining services bring precision machining capabilities directly to your site. This portable solution reduces downtime and eliminates the need for component disassembly. Our equipment can perform milling, boring, and facing operations with high accuracy in any location.

Stress Relieving

We employ advanced stress-relieving techniques, such as thermal and vibration stress relief, to reduce residual stresses in welded and fabricated components. This process enhances material performance and longevity by preventing distortion and improving fatigue resistance.

Hydraulic Pressure Testing

Our hydraulic pressure testing services verify the integrity and performance of hydraulic systems. We use test rigs capable of pressures up to 30,000 psi. We perform leak testing, burst testing, and functional testing, ensuring components can withstand operating pressures and preventing failures in many applications.

Pipe Bending and Fabrication Facility

Our pipe bending and fabrication facility is equipped with CNC-controlled bending machines and welding stations. We can handle various pipe diameters and materials, delivering custom-fabricated pipes that meet precise specifications and industry standards.