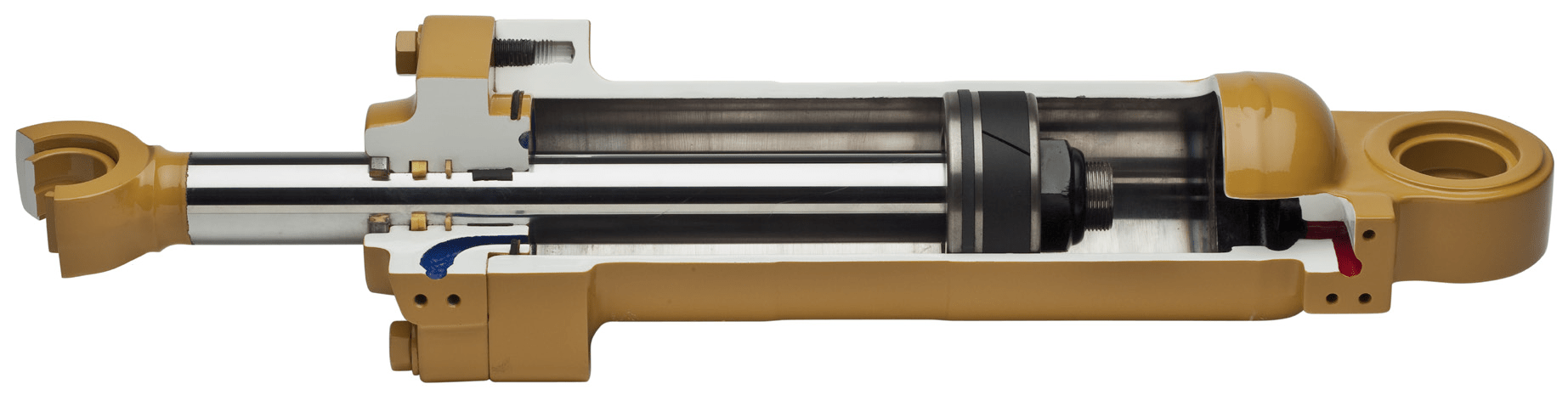

Hydraulic cylinders play a pivotal role in oil and gas and other industries, providing the muscle behind heavy machinery. Over time, even the most robust cylinders can suffer from wear and tear, leading to decreased efficiency or complete failure. We work with all cylinder brands and types and restore seals, polish rods, hone tubes, and more.

Our Process

Initial Assessment

Once we receive an enquiry, we will visit the site for an initial assessment, and if required, we will handle the logistics, transporting the hydraulic cylinder to our advanced facility for thorough inspection and making necessary reports in accordance with the work's scope and all of our noted observations.

Dismantling

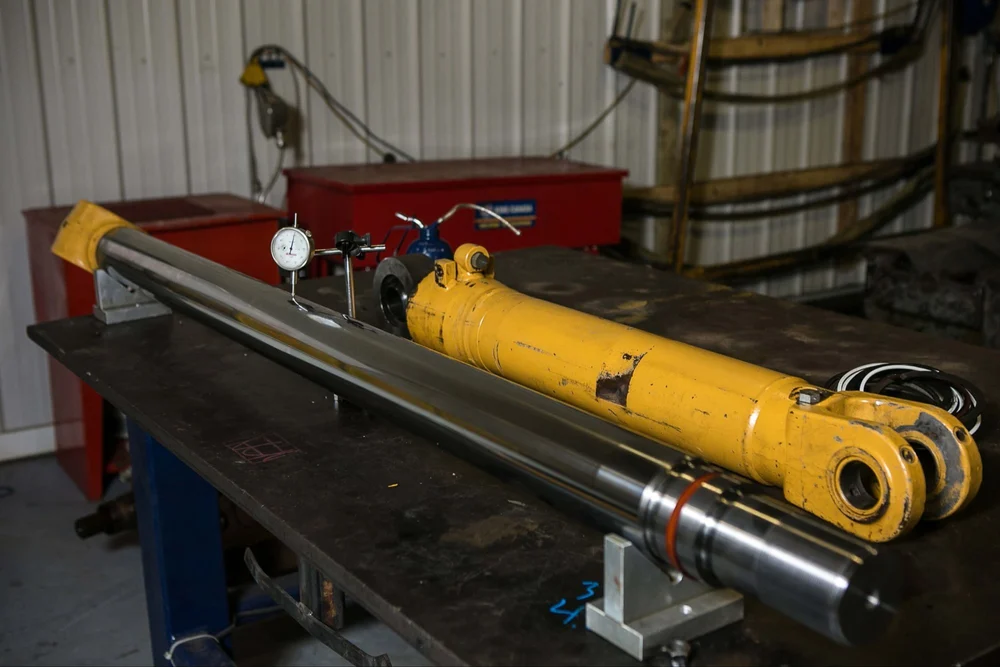

Our skilled technicians carefully dismantle the cylinder, readying it for a thorough inspection. We will conduct a detailed examination of each part to pinpoint issues like worn-out seals, internal leakages, load not holding, scored piston rods, scored bores, and so on. Once done, we prepare a detailed scope of the work based on cylinder condition and submit it to the client for approval.

Repairing

Once we get approval from the client, we'll proceed with either repairing the part or replacing the defective part as per the defined scope. Below are some of the main services we do:

Seal Replacement - Worn-out seals causing leaks and pressure drops? We replace them with high-quality, durable seals to restore your cylinder’s integrity and efficiency.

Rod Repair - If there are pitting marks and heavy scoring observed, the rod will be processed through the pre-grinding (rechroming-chrome plating-finish grinding) to ensure the part is restored to its original size and specifications.

Bore Repair - If we detect bulging, we will manufacture and replace the cylinder. For heavy scoring, it is repairable, so we will proceed with honing the surface.

Part Replacement or Manufacturing

We replace parts like bearings and pins. If other parts, such as piston rods, barrels, valves, cams, glands etc, are beyond repair, we manufacture and replace them as well.

Reassembling and Testing

After installing new or repaired parts, we reassemble the cylinder with precision.

Rigorous Testing - Each cylinder undergoes test pressure, ensuring it meets or exceeds OEM specifications.

On-Site Verification

After factory testing, we either dispatch the cylinder to the client site or fix it on-site and conduct testing and trials as per the project scope.

Contact us to request further information about our products and services

Connect with our Expert

Why Choose Us for Best Hydraulic Cylinder Repair?

-

Fast Turn-Around Time : We understand the importance of minimizing downtime. Our efficient processes and skilled technicians ensure quick repairs, getting your equipment back in operation as soon as possible.

-

Experienced Technicians : Every repair is treated with meticulous care. Our team of experts employs advanced techniques and high-quality components to guarantee long-lasting and reliable performance.

-

Quality Repair Services : From minor seal replacements to major overhauls, we handle a wide range of repairs. Our comprehensive services address all your hydraulic cylinder needs.

-

Convenient Spare Part Fabrication : Need a specific part that's difficult to find? Our in-house fabrication capabilities allow us to quickly produce custom spare parts, saving you time and hassle.

-

Cost-Effective : Repairing rather than replacing hydraulic cylinders can save significant costs.